The Scope of Application

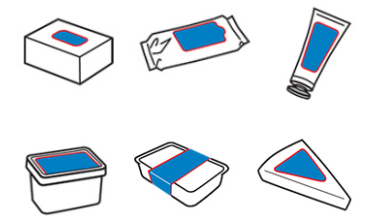

The model top surface labeling machine suit for box, carton, bags, container, cups and so on.

Equipment function characteristics

1) Control system: German SIEMENS PLC control system, with stable operation and extremely low failure rate.

2) Betjeningssystem: Tysk SIEMENS 7 tommer berøringsskærm, direkte visuel interface let betjening, med kinesisk og engelsk, også rig med hjælpefunktion og fejlvisningsfunktion.

3) Mærkningssystem: Hele etiketteringsmotoren bruger tysk Avery-mærke, kun SKILT med denne slags mærkningsmotor i Kina, med temmelig høj konkurrencefordel;

4) Alarmfunktion: Såsom etiketudslip, etiket ødelagt eller anden funktionsfejl under maskinens arbejde, vil alarme og stoppe med at arbejde.

5) Maskinmateriale: Maskine og reservedele bruger alle materiale S304 rustfrit stål og anodiseret ældre aluminiumslegering med høj korrosionsbestandighed og aldrig rust.

6) Others: Low voltage circuit all use the German Schneider brand. The bearing use IKO .

Teknisk parameter

| Køreskimmel | Tysk Avery |

| Kapacitet (Stk / min) | (20-200stk) Afhænger af flaske og etiketstørrelse |

| Transportørhastighed (m / min) | ≤35m |

| Mærkatmateriale | Selvklæbende klistermærke, gennemsigtig eller uigennemsigtig |

| Egnet etiketstørrelse | Bredde: 15-160mm Længde: 15-300mm |

| Egnet flaske størrelse | kan tilpasses |

| Spænding | AC110V / 220V / 380V |

| Driftsretning | venstre eller højre |

| Mærkningsnøjagtighed | ± 1,0 mm |

| Total styrke | 550W |

| Maskinstørrelse | 1800x800x1600mm |

| Ingen | Navn | Enhed | Brand |

| 1 | PLC-styringssystem | 1 sæt | SEMIENS |

| 2 | Berøringsskærm | 1 sæt | SEMIENS |

| 3 | fotoelektrisk sensor (checkflaske) | 1 sæt | Japan KEYENCE |

| 4 | Photoelectric sensor (Check opaque label) | 1Indstil | Tyske Lueze |

| Photoelectric sensor (Check transparent label) | 1Indstil | USA løve | |

| 5 | Mærkningsmotor | 1 sæt | Tysk Avery |

| 6 | Køre | 1 sæt | Tysk Avery |

| 7 | Hovedtransportmotor | 1 sæt | Tyske JSCC |

| 8 | Separat motor | 1 sæt | Tyske JSCC |

| 9 | 9 Speed Controller | 1 sæt | Tyske JSCC |

1. The machine mainly uses SUS304 stainless steel and aluminum alloy (sandblasting anodizing) material.

2. The host is driven by advanced servo system, with high speed and high positioning accuracy.

3. Optoelectronic products are imported famous brands, with high stability and accurate detection.

4. PLC with man-machine interface control, operation is concise and clear.

5. The host position can be flexibly adjusted on the top, bottom, front and rear, parallelism and verticality.

6. The speed of conveyor belt can realize digital adjustment of touch screen.

7. The device can operate independently and can also be connected to the production line.

Flad etiketteringsmaskine

Anvend på alle former for flad produktmærkning. (for eksempel papirkort, selvforseglende taske, karton, madkasse, medicinboks, kosmetikboks, papirvarer, CD-cd, kort, elektrisk tavle, alle former for oliekedel osv.)

Teknisk parameter:

| Maskinmodel | Flad etiket maskine |

| Maskinstørrelse | 2000 (L) x 700 (B) × 1600 (H) |

| Mærkehastighed | 30-200stk / min (afhængigt af flaskens størrelse og etikettens længde) |

| Objektets højde | 30-200mm |

| Objektstykkelse | 20-200mm |

| Mærkets højde | 5-180mm |

| Mærkets længde | 20-300mm |

| Mærkningsnøjagtighed | ± 1 mm (Beregn ikke fejlen på flaske og etiket) |

| Scollinner diameter | 76mm |

| Scollouter diameter | 350mm |

| Strømforsyning | 220v 50 / 60hz 0,75Kw |

| Maskinens vægt | 180 kg |

Hovedtræk:

1. The machine mainly uses SUS304 stainless steel and aluminum alloy (sandblasting anodizing) material.

2. The host is driven by advanced servo system, with high speed and high positioning accuracy.

3. Optoelectronic products are imported famous brands, with high stability and accurate detection.

4. PLC with man-machine interface control, operation is concise and clear.

5. The host position can be flexibly adjusted on the top, bottom, front and rear, parallelism and verticality.

6. The speed of conveyor belt can realize digital adjustment of touch screen.

7. The device can operate independently and can also be connected to the production line.

Pakning og levering

| Emballage | |

| Størrelse | 2900 (L) x 1800 (B) × 1650 (H) |

| Vægt | 550 kg |

| Emballeringsdetaljer | * Udenfor emballage: Standard trækasser * Indvendig emballage: Strækfilm indpakket * Emballering i henhold til kundens krav. |

Vores service

1.Warranty time: Two years,from the date which the product is qualified commissioning Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be count on buyer.

2.Commissioning services: The product's installation and commissioning at the demand side,our engineers will not leave there until get your agreement.

3. Training services: our engineers will train your staff to operate it during the period of installation and commissioning,they will not leave there until your staff can operate it properly and normally.

4. Maintenance services: Any malfunction happened,once you enquiry us,we will .reply you within 48 hours except the special reasons.

5. Lifelong services: We provide lifelong services for all the products we sold out,and supply the spare parts with discount price.

6. Certificate services: We can provide related certificates to customers freely according to the request of customers.

7. Inspection services: You can ask the third part inspection company or your inspector to inspect the products before shipment.